Equipment name: Ultra-high-speed fully automatic vest bag making machine

Dual-line high-speed vest bag with edge insertion function.

A variety of bag making specifications are available.

Brief Introduce:

It is applied to produce the printed double-lane or non-printed vest bags/ t shirt bags, using HDPE, LDPE roll film. It adopts PLC control,double servo motors control and the touch screen actual display to finish the feeding, sealing, cutting, punching in one process, which can save man-power greatly and yield good economic result.

Technical parameters:

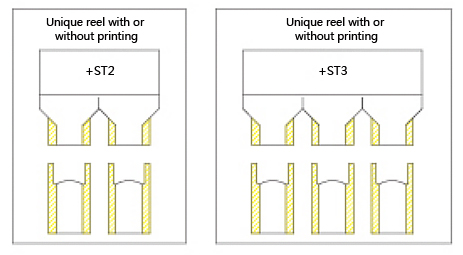

| Model | CW-500V | CW-400V2 | CW-300V2+ST2 |

| Bag length | 370-700mm | 370-700mm | 370-700mm |

| Width of bag making(Max.) | 500mm | 400mmx2Line | 300mmx2Line |

| Width size of cutting knife | 580mm | 480mmx2Line | 380mmx2Line |

| Speed of bag making(Max.) | 250pcs | 250pcsx2Line | 220pcsx2Line |

| Line speed | 125M/min | 125M/min | 100M/min |

| Total power | 10KW | 18.5KW | 20KW |

| Machine weight | 2800kg | 3100kg | 3800kg |

| Machine dimension | 8000x1350x1800mm | 8000x1850x1800mm | 10000x2000x2000mm |

Unwinding part:

- Adopt two-line independent unwinding design, AC motor drive, active unwinding, large roll diameter design, reduce the number of shutdowns.

- The tension is controlled by the inverter, and the speed changes automatically with the change of speed and roll diameter.

- The unwinding is equipped with an air expansion shaft, and air pressure is used to load the material to reduce manpower. The maximum roll weight is 120kg.

- Equipped with an automatic shutdown device for no material and broken material.

Printing electric eye and bag feeding:

- It has blank bag and printed bag color mark tracking mode.

- The color mark electric eye adopts German (SICK) photoelectric eye, zero failure, and accurate sealing and cutting size.

- The bag feeding is driven by Japanese Yaskawa servo motor, high-speed transportation, and precise positioning.

- The bag feeding adopts air blowing, and the air blowing is independently controlled up and down, and the air pressure is adjusted independently.

Intermediate deviation correction part:

- Adopt two-line independent EPC design to guide the film to the correct position.

- Two-line EPC is independently controlled and has an error alarm prompt.

Sealing and cutting knife and whole-book stacking device:

- Reversible heavy-duty side sealing knife, humanized structural design, fast flipping, simple cleaning.

- The temperature of the upper and lower sealing knives of the two lines is independently adjusted, and controlled by an intelligent temperature controller.

- The temperature of the middle cutting knife is independently adjusted.

- The whole-book stacking of bags has a swing design, and the upper and lower bag sealing lines do not overlap to avoid sticking to each other.

Finished product stacking and collection part:

Each batch of bags is automatically stacked, the collection table is automatically shifted, and the whole book is output, which is convenient for collection and packaging.

It has the function of folding the whole bag in half, eliminating manual folding.

The product bag flattening function removes air and reduces the size of the box packaging.